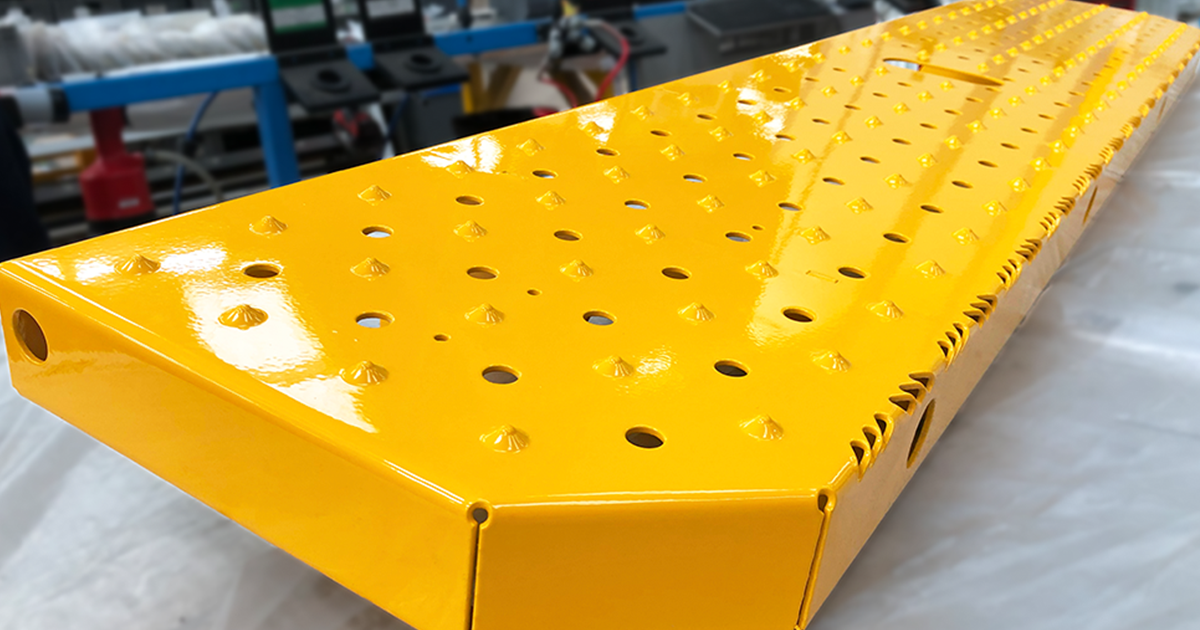

Atlas powder coating operate an ITW Gema paintline with automated and manual spray facilities as well as quick change booth for rapid colour change.

We operate an innovative pre-treatment system utilising a saline base Oxsilan solution which offers high corrosion resistance with much lower environmental impact than Zinc or Phosphate alternatives.

The entire powder coating process can be simply broken down into 4 stages:

Stage One – Pre-treatment

Pre-treatment is comprising 5 sub-processes:

- Process 1: Is a highly Alkaline cleaner for steel alloys and zinc-coated steels

- Process 2: Cold rinsing from the main water supply.

- Process 3: Rinsing with Demineralised water

- Process 4: Oxsilan 9810 is a silane-based multi-purpose liquid pre-paint treatment

- Process 5: Single ring rinsing with Demineralised water

The integrity of the pre-treatment system is maintained by rigorous use of SPC controls and reinforced by regular testing of production sample panels by an independent test laboratory.

Oxsilan 9810 is an innovative new pre-treatment system launched in the UK in 2006, relying on chemical bonding, as opposed to traditional metal coating. It delivers corrosion protection to products, that out-performs an equivalent zinc phosphate system, without the environmental and associated cost disadvantages.

Stage Two – Drying

Components are then passed through the drying oven to remove residual liquid from the parts before any powder is applied. The drying oven, set at approximately 180°C, dries the pre-treated components ready for application of the powder paint.

Stage Three – Powder Application

A combination of automatic and manual spray operations ensures that a controlled and consistent powder film build is achieved.

As work passes through the spray booth, controlled amounts of powder are applied by automatic Electrostatic spray guns mounted on automatic reciprocators. Difficult areas not reached by this process are coated by an independent manual spray operation.

Both manual and automatic guns are computer controlled to ensure consistent powder application.

The spray booth benefits from an automatic part recognition system, which continually adjusts the stroke and operation of the guns to optimise the process for individual items.

Atlas has a quick colour change spray booth to assist in minimal downtime during colour changes. Overspray powder is reclaimed through a rigorous filtration system, allowing excellent material utilisation whilst minimising environmental impact.

Stage Four – Stoving

After powder coating components pass through a gas-fired tunnel oven, the deposited powder film flows then cures as the metal temperature increases to that recommended for the powder applied. During the course of this process, the particles of powder bond together to produce a continuous smooth finish.

Where primer coats are required:

If a primer coat is initially applied, during the subsequent top coat application, all elements of the pre-treatment will be switched off, allowing the top coat to be applied directly to the primed surface.