ABOUT US

Atlas Powder Coating was established as part of the Bri-Stor Group back in 1989, originally to finish products manufactured by sister company Alpha Manufacturing for -Bri-Stor Systems – also part of the Bri-Stor Group.

Driven by a commitment to quality and efficiency, Atlas were soon able to offer services externally and has since grown to become the powder coating specialist of choice for many companies in the midlands across the UK.

CORPORATE

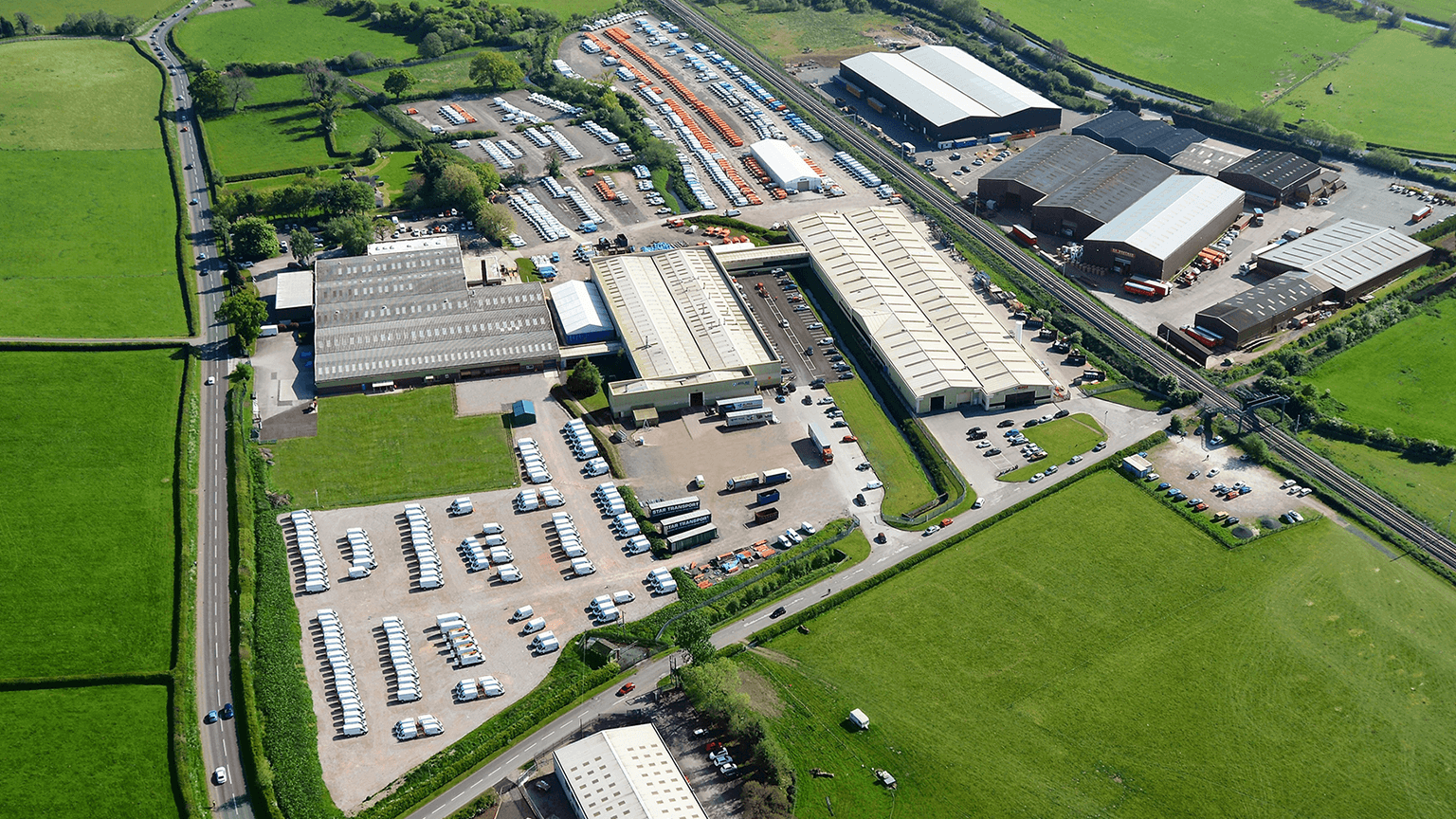

The Bri-Stor Group, comprising Atlas Powder Coating, Alpha Manufacturing and Bri-Stor Systems was born in 1983 with the conception of light commercial vehicle converters Bri-Stor Systems. Precision sheet metal fabricator Alpha Manufacturing was established in 1989, with Atlas Coating launched shortly after.

Still a family owned and run group of companies today, the Group employs around 400 people and occupies a 35-manufacturing facility in Hixon, Stafford. Across all three Bri-Stor Group companies, our values of innovation, dedication and commitment to quality remain consistent.

FACILITIES

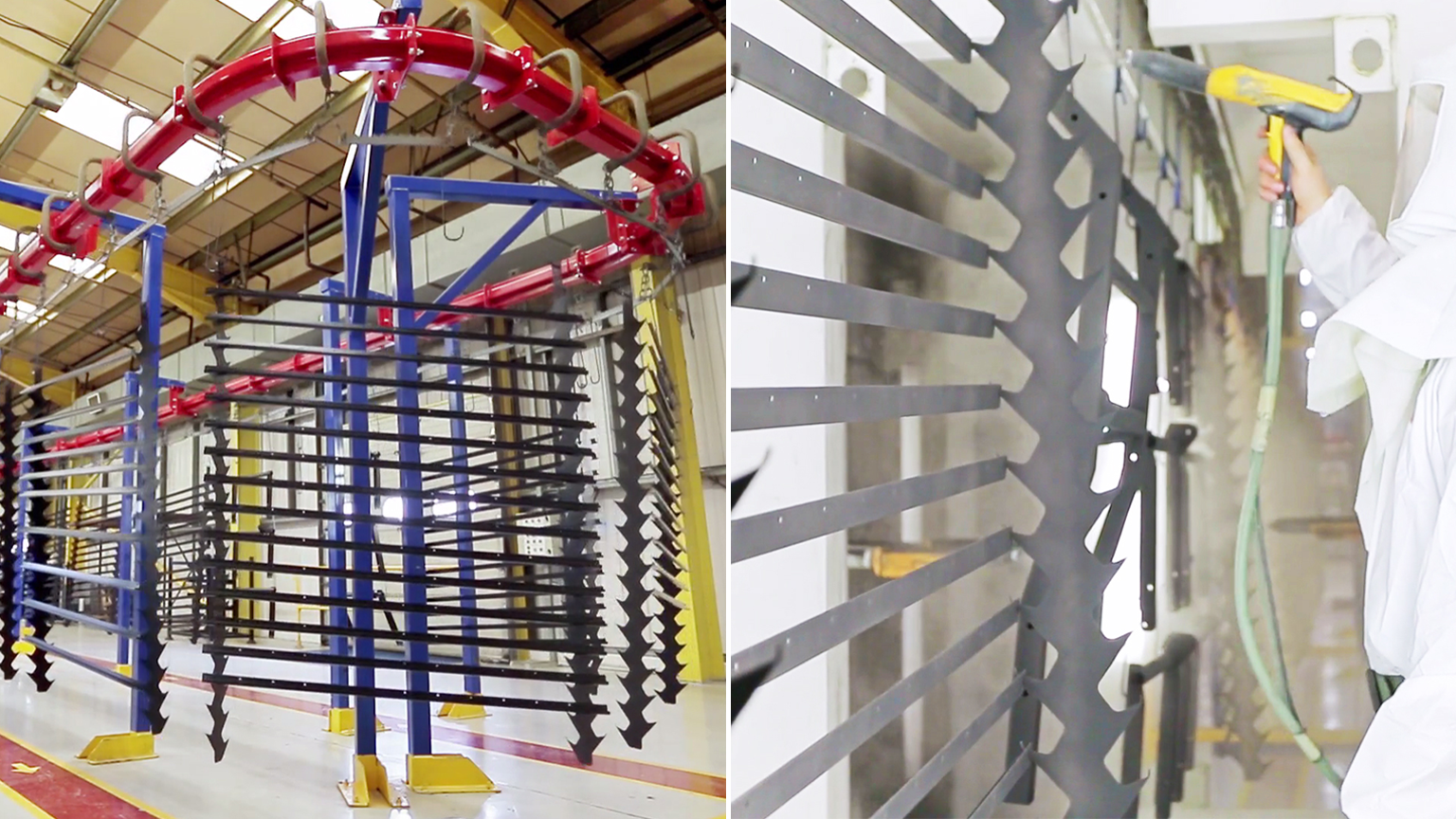

Consistent investment across the Bri-Stor Group means that Atlas Powder Coating operate one of the most cutting edge, efficient and environmentally friendly plants in the industry.

Our automated ITW Gema line features both automated and manual spray booths for maximum coverage and quality. A quick-change booth allows us to rapidly swap colours mid cycle in around 7-10 minutes, allowing for ultimate flexibility and speedy service. Unlike other powder coaters, we are able to complete multiple colour changes in a single day.

Our site is perfectly located in the Midlands, near to major transport links, enabling us to offer services across Staffordshire and beyond. Our 35 acre site means we have ample space for our secure holding area, making storage delivery/ collection of products as simple as possible.

QUALITY

Quality has always been at the forefront of our service. Atlas Coating was founded initially to service sister company Bri-Stor Systems in their light commercial vehicle conversions for major fleet customers, where finish quality was paramount. This attitude remains today, with quality being the focus of all we do.

We are certified to ISO:90001, ISO 14001 & OHSAS 18001 standard and are regularly audited, both internally and externally to ensure our processes, systems, materials and equipment are to standard. Our machinery is regularly inspected by our on-site maintenance team, working to strict TPM’s to ensure ultimate reliability and quality of our equipment.

We offer a complete end-of-line inspection process, including CMM 3D Faro arm inspection. We employ a dedicated quality and inspection team who check products throughout the process and conduct thorough final inspection prior to dispatch.

We offer a 1000-hour salt spray guarantee to all our customers, which is well over the standards most commonly required by customers.

ENVIRONMENTAL

Our commitment to the environment is reflected across our entire operation, from our processes to materials, equipment and packaging. Our innovative five-stage pre-treatment process utilises Oxsilan, which is a Saline based solution, as opposed to more harmful Zinc or Phosphate alternatives used by many powder coaters. This allows us to significantly reduce our environmental impact, whilst still offering unbeatable corrosion protection and durability.

Powder coating as a process is naturally more eco friendly than wet spray alternatives due to its lack of VOC (Volatile Organic Compounds). To further improve our Eco credentials, we buy only the highest quality powders from leading suppliers to reduce improve quality and waste.

We work with customers from the outset to create and implement specific packaging specs in order to both safeguard quality and reduce potential waste. On-site waste management processes, including cardboard compacting ensure we minimise our environmental impact through waste.